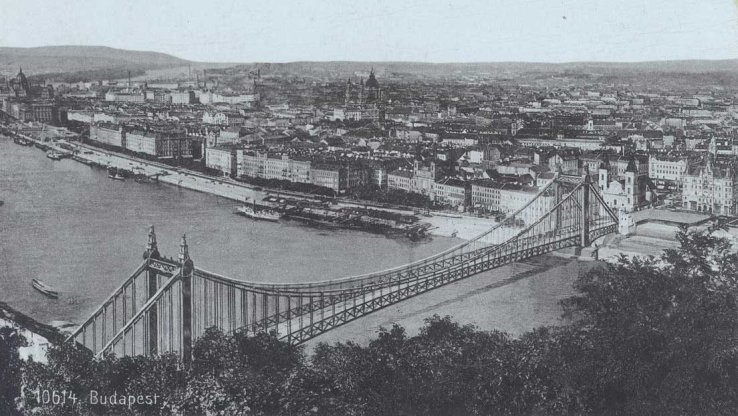

In the latest temporary exhibition of the Museum of Transport, which presents the unrealised Budapest plans, a separate section deals with the road tunnels under the Danube. The fact that the vehicles could cross under the river and not over it already stirred the imagination of designers in the 19th century.

During the planning of the Árpád Bridge, there were several suggestions that tunnels should be built instead of the bridge. One of the reasons behind the idea was that in the event of a possible war, tunnels are more difficult to destroy than bridges. In the 1930s, they were able to seriously consider the possibility of a road tunnel, because at that time a tunnel with a relatively large cross-section was actually built under the river, although it was not yet for traffic.

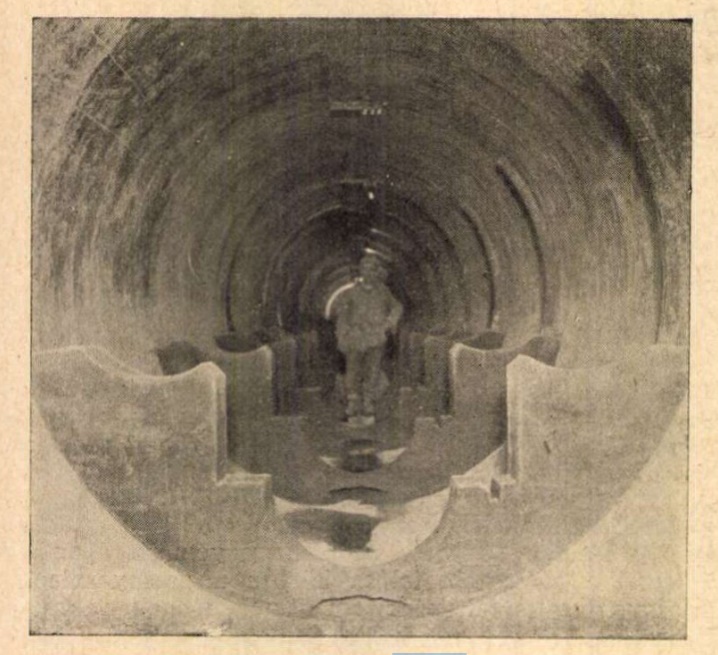

Cross section of the completed tunnel (Technika, 1 November 1936)

In the early 1930s, the Budapest Waterworks planned to build a total of three tunnels between Szentendre Island and Pest under the Danube, thus improving the capital's water supply. A tender for the construction of the tunnels was announced in August 1930. 16 applicants submitted materials for the construction, 15 of them would have built using a pneumatic, i.e. overpressure, method. However, the proposal of Pál Káldor and László Mattyasovszky included a cheaper, non-compressed air system, which was already successfully used in Berlin. This solution was cheaper than the compressed air, i.e. pneumatic method, when the work space is virtually hermetically sealed and filled with high-pressure air, which keeps the intruding water out. The method of working with high-pressure air is complicated and, if used improperly, is very harmful to the health of workers.

However, the experts did not consider the procedure outlined (i.e. non-compressed air) by the two applicants to be feasible here, so they announced a new tender. However, even in this new tender, the offer of the Káldor-Mattyasovszky company, which now proposed a shield drilling method, was also the cheapest, and finally this company's offer of 1.5 million pengos was accepted.

The drilling of the first tunnel itself began 90 years ago, on 27 June 1932. The newspaper Ujság reported on this on 26 June 1932 as follows:

"On Monday morning, a special Hungarian tunnel drilling machine will start working at Megyér, twenty-eight metres below the bed of the Danube. A 45,000-kilogram drilling and masonry machine will drill and build masonry in one session."

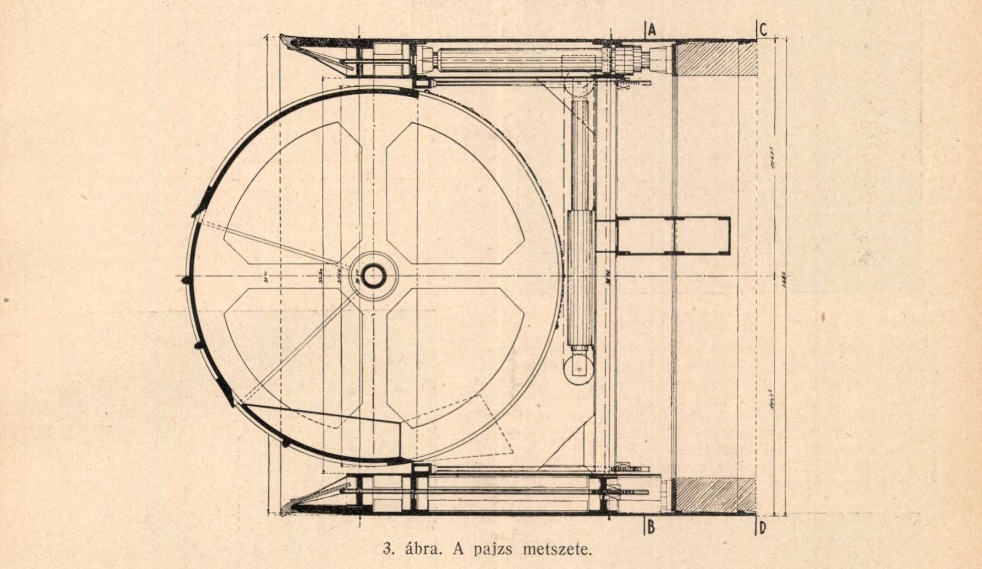

The article presented in detail – according to the paper – the most modern drilling machine in the world, which was designed by engineer Pál Garas, and which, according to the contractors' hopes, does not require the creation of a high-pressure workspace:

""The greatest technical miracle of this Hungarian tunnel-making machine construction is that while it grinds the earth in front, it walls the excavated circular layer at the back. It is therefore not necessary to drill for eight hours, as before, and wall up the drilled tunnel in the other eight hours. [...] Masonry is carried out in such a way that the rotating shaft that operates the rotating excavator at the front lifts the rotating masonry ring in a circular shape, which also puts the two-metre-long, 60-centimetre-wide and 600-kilogram reinforced concrete ring sections into place. This machine, according to the design, produces 60 centimetres of finished tunnel per hour. It digs itself into the ground 60 centimetres in the front and creates a 60-centimetre reinforced concrete wall in a circular shape at the back."

The paper immediately asks the question, if it is so simple and cheap to build a tunnel, why do bridges need to be built so expensively?

Section of the drill shield. In contrast to today's shields, the casing of the cylinder of the drill head drills here, in today's machines the drill head is a huge "plate with teeth" (Technika, 1 November 1936)

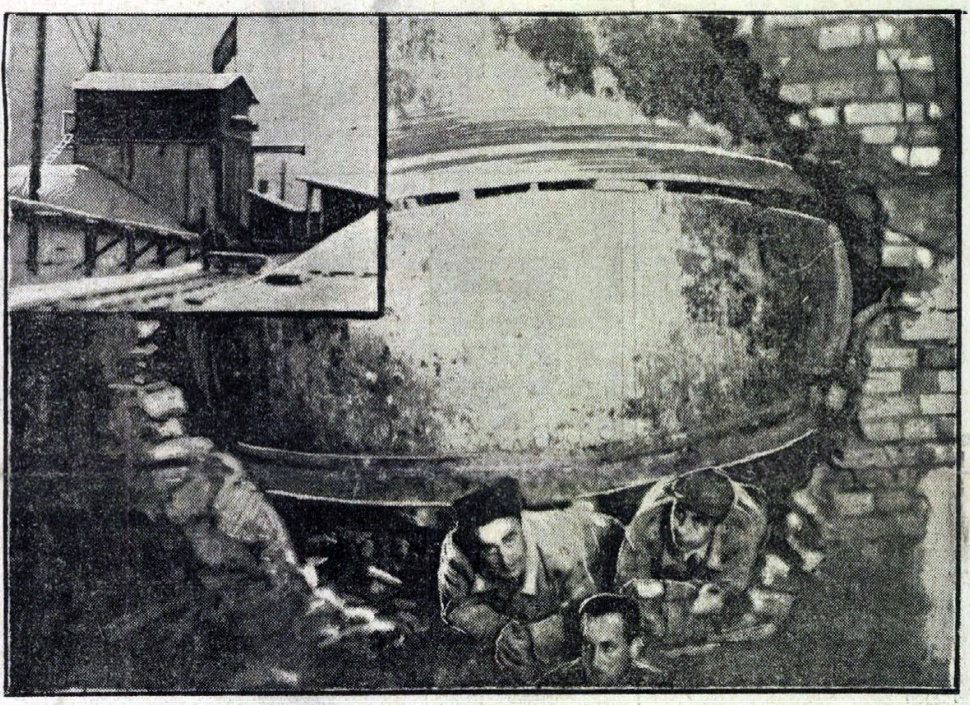

However, the construction of the tunnel was not easy. The Hungarian-designed equipment already broke down in September 1932, and it turned out that the equipment manufactured by the Hungarian Radiator Factory was not even suitable for this task. At that time, foreign drilling equipment was brought, until then, of course, the work stopped. It really looked like the whole tunnelling thing was going to be a huge scandal. Finally, in 1933, the contractors admitted failure and, involving other partners, switched to "traditional" pressurised construction. However, bad luck did not escape the builders even then, because in 1934 water intrusion made the work difficult.

In spite of all this, the first tunnel under the Danube was completed relatively quickly, in 1935, and this finally filled everyone with satisfaction. The 600-metre-long tunnel was built with a diameter of two and a half metres, and they were able to place the water pipes in such a way that the tunnel remained passable next to them. Of course, this route was not suitable for everyday use, but only for inspection.

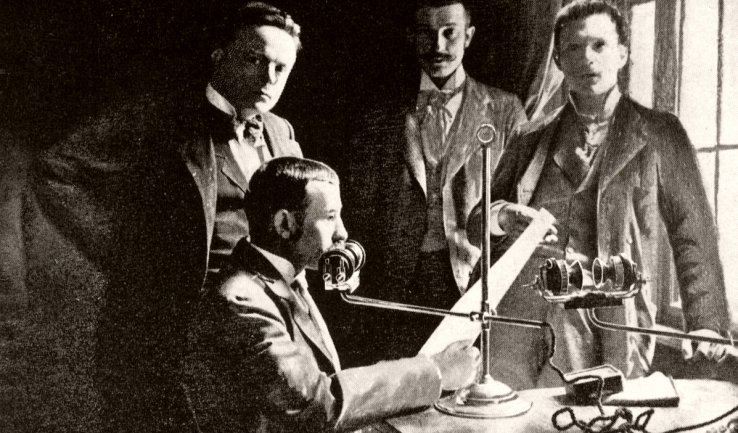

The historic moment, the workers climb out from the other end of the drilled tunnel under the drill head (Friss Ujsag, 5 December 1935)

Encouraged by this success, several people proposed the construction of road tunnels, and it was practically constantly on the agenda in the 1970s and 1980s.

However, no road tunnel has been built under the Danube to this day, but in addition to the waterworks tunnels, four subway tunnels (pairs of Metro 2 and Metro 4 tunnels) connect Pest and Buda underground, and connections were established under the river for other public utilities.

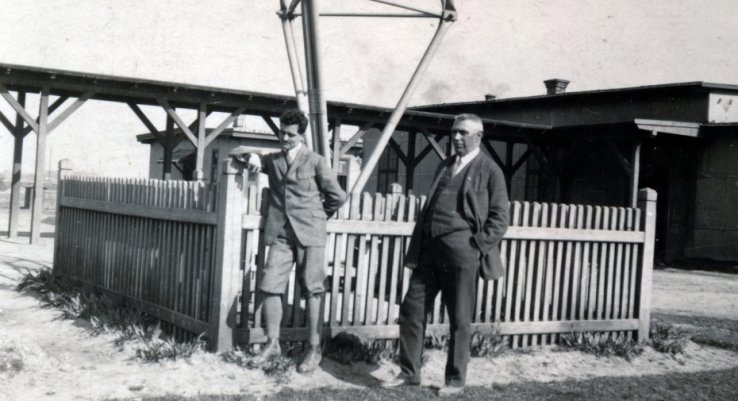

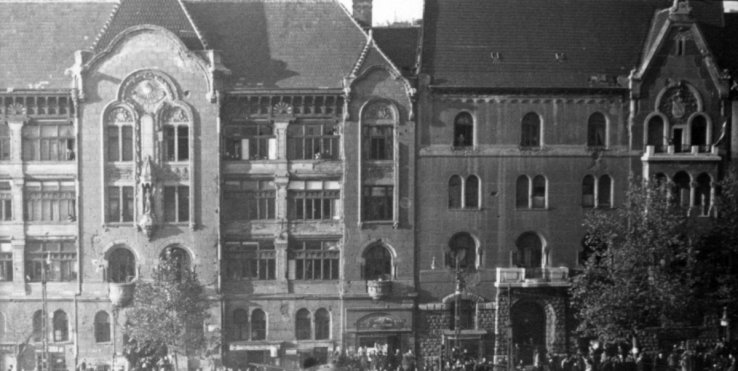

Cover photo: Capital leaders inspect the tunnel construction (Source: Képes Pesti Hírlap, 13 September 1935)

Hozzászólások

Log in or register to comment!

Login Registration