The first roadway of Chain Bridge, handed over in 1849, was constructed quite differently than the current one. Hanging rods hung from the chains in the same way as now, but twice as frequently. Each pair of suspension rods was connected to a cross girder, which was made in Dernő, now part of Slovakia, in the Andrássy Castle's foundry, and these cross girders were placed across the roadway - as it is shown in their names - and they upheld the road and pavements.

These cross girders were approximately 1.8-1.9 metres apart. Not exactly at the same distance, because the chain links were of the same length, because of this, as the chain row rose steeper, the successive cross supports were placed more and more densely. But this did not really bother anyone, because wooden beams were bolted to these structures, parallel to the roadway, and even small holes were created directly for the beams.

The decking was placed on the beams, one or two layers (this changed several times during maintenance), and then the 13-centimetre-high wooden blocks came on top of that. The pavements were designed much more simply, there were only smooth planks bolted to the cross girders.

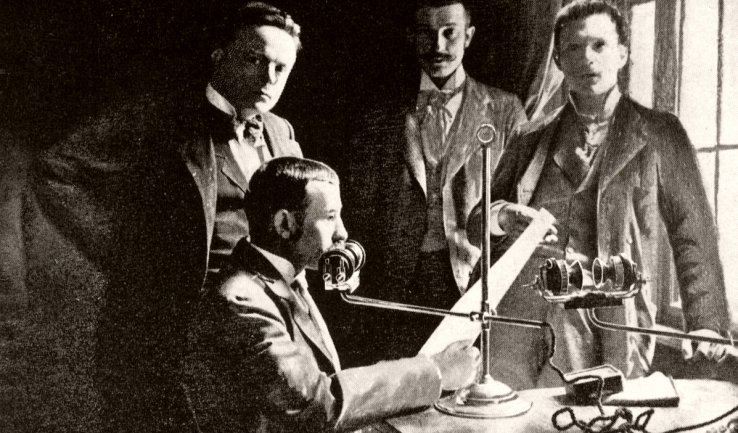

Demolition of the old bridge in 1914. The closely spaced cross girders can be clearly seen, on which a temporary railway track was built to serve the demolition (Photo: Hungarian Museum of Science, Technology and Transport Historical Photographs Collection, Reference No.: TFGY 372.10)

There were two reasons why so much wood was used in the construction of the bridge track. On the one hand, the entire bridge was much lighter this way, and on the other hand, wood, as an elastic material, helped to dissipate the vibrations caused by the carriages travelling on the bridge. However, the wood deteriorated relatively quickly, as it was worn and destroyed by water and traffic, so these parts had to be replaced very often. In the case of wooden blocks, the time for mandatory replacement usually came at 6 centimetres, but most of the time they did not wait so long. Sometimes, however, the entire wooden structure had to be rebuilt, which happened shortly after the state bought the bridge in 1870.

The bridge deck was practically completely replaced in 1874. The task was entrusted to an American contractor who had previously also made the wooden cube covering of the Avenue, but the method he used was really cheap but less durable. Due to the fact that the pavement was destroyed very quickly, in fact within a few years, a huge scandal broke out, for which the entrepreneur did not stay, he left the country.

The old deck was picked up and what was usable was auctioned off. A tender was issued for the construction of the new track, which was won by Guidó Rütgers' Austrian company. Not only did he have to build the track, but he also had to maintain it, a contract was signed with him for a total of 12 years. In the following period, this company, therefore, maintained the roadway of the bridge. In the meantime, they also realised that it is not advisable to lay the wooden cubes in straight rows, and for timely replacements, they switched to the solution of laying them in diagonal rows. From time to time it was suggested to replace the wooden beams and planks with steel, but this was considered expensive and there was also fear that the new track would not be flexible enough, which would be harmful to the cast iron cross girders.

During the complete reconstruction of the Chain Bridge, it was naturally out of the question that the roadway of the bridge should be made of wood. On the new steel bridge, the much rarer cross girders were already connected with elements made of metal, so-called zores beams. These are rain-gutter-like elements with a small rim on the side and they are placed with the vault facing upwards.

At the Chain Bridge, the zores beams were not placed close together, but at a small distance from each other, and the gaps were filled with eternit sheets. This was followed by several layers of asphalt concrete and asphalt, then wooden blocks again.

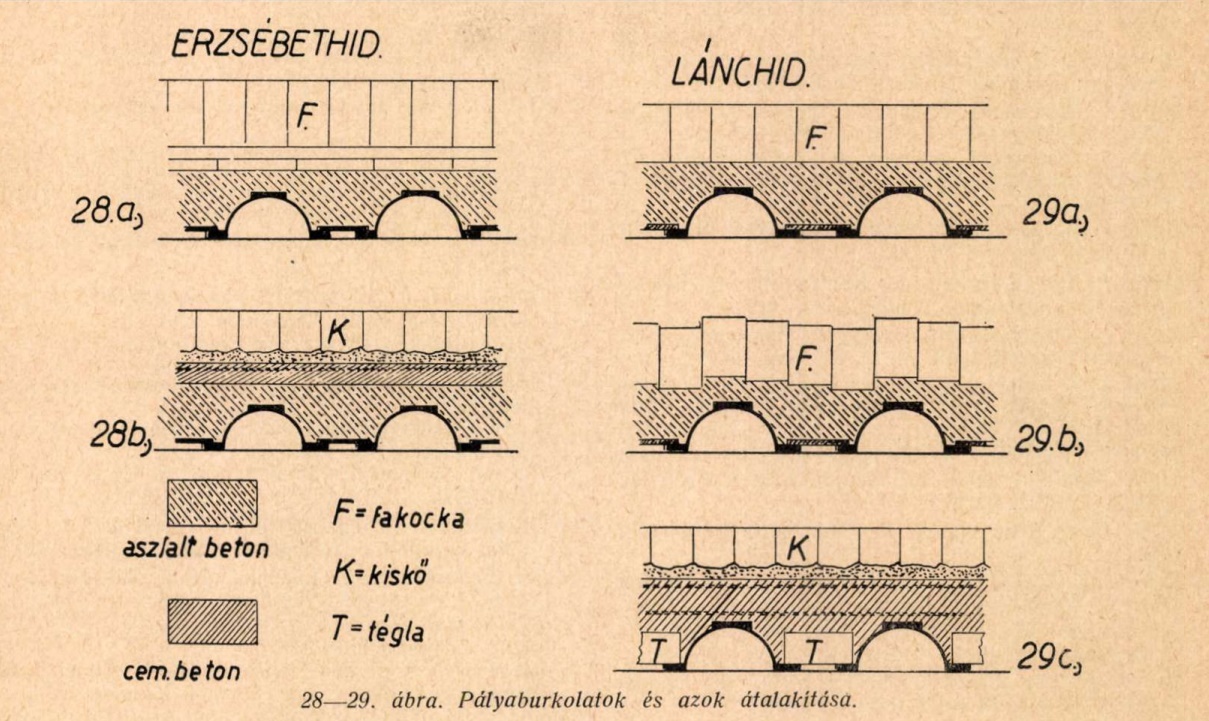

The roadways of the Erzsébet Bridge, which was handed over in 1903, and the Chain Bridge, which was reopened in 1915. In the upper pair, it can be seen that the layer of planks from under the wooden blocks was not left at the Erzsébet Bridge, but it was at the Chain Bridge. At the Chain Bridge, the lower picture shows the structure of the roadway after repair (Source: István Gállik: Történelmi visszapillantás régebbi Dunahídjaink építésére [A historical look back at the construction of our older Danube Bridges], Technika, 1941/2 issue)

However, the people of Budapest could not be happy with the new bridge, which was handed over in 1915, for long, because the roadway deteriorated incredibly quickly, waves and grooves formed. The scandal was huge, in 1917 the Ministry of Finance ordered an investigation, Szilárd Zielinski was appointed to investigate the errors, although due to the war they could not really think about repairs. The situation became so bad that the bridge had to be closed to larger vehicles in 1919. In the meantime, Szilárd Zielinski, the renowned engineer, very thoroughly explored the errors. He came to the conclusion that an intermediate layer of planks had been left out during the construction, so the oil leaking from the oil-soaked wooden blocks had simply turned the concrete-asphalt material that made up the body of the road into bitumen mud, and to add to the errors, the eternit sheets between the zores beams had also broken.

The entire roadway had to be taken up, the eternit sheets were replaced with bricks, and a stronger reinforced concrete foundation was built. Since wooden blocks were simply unobtainable after the war, the bridge was covered with small blocks of stone, which were finally replaced with asphalt in 1929. On the new bridge, the pavements were already covered with asphalt, there was also a problem with this, it blistered, but this could be handled more simply.

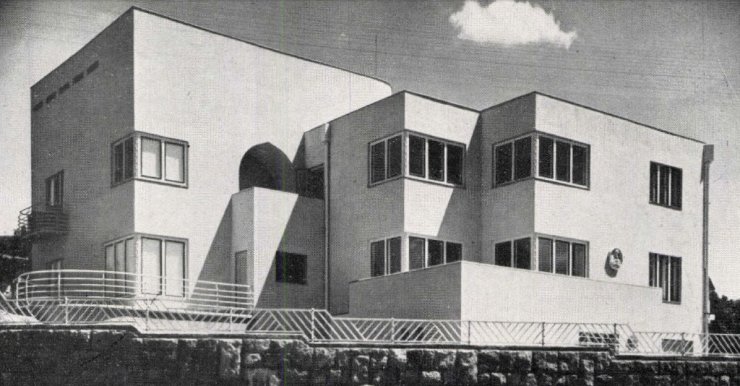

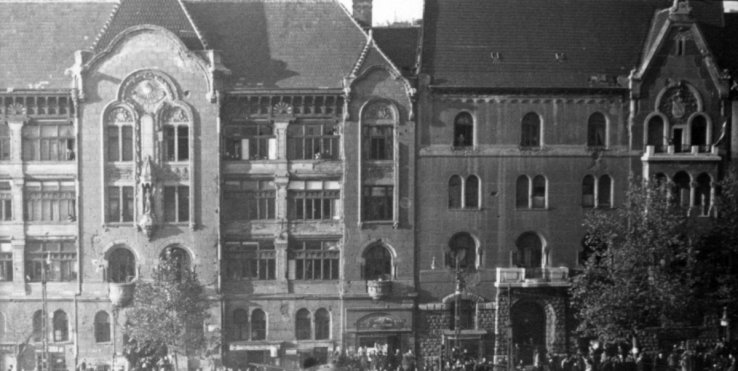

Asphalting of the road in 1949 (Photo Fortepan, Uvaterv)

During the post-World War II reconstruction, the bridge was rebuilt according to the plans of 1914, with the difference that the cross girders were welded structures, instead of using zores beams, a strong reinforced concrete deck slab was built, and the asphalt was laid on it. However, this reinforced concrete slab was not insulated, and the infiltration of water and the winter salting applied since the 1960s completely destroyed this deck slab in the last 70 years.

In recent decades, there have been minor modifications to the deck slab, the dilation equipment (which allows the bridge to move) has been replaced, the bridge has been re-asphalted several times, but the lack of insulation has not been solved. The old reinforced concrete slab, built in 1949, is now so damaged that it was not worth repairing, which is why it was replaced with a modern and also much lighter steel structure deck slab during the current renovation.

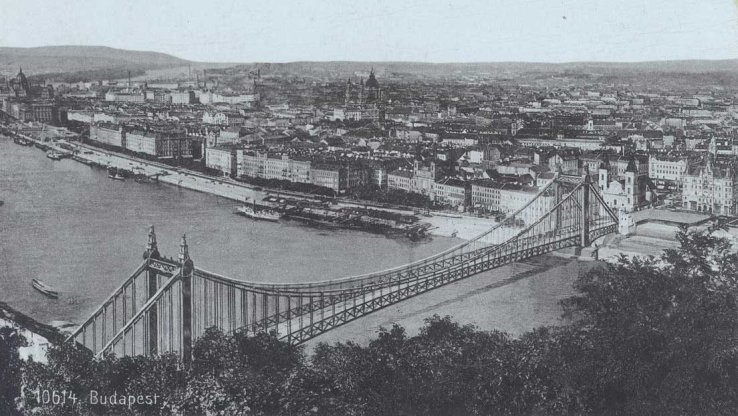

Cover photo: The Chain Bridge in the 1930s (Photo: Postcard collection of the Hungarian Museum of Science, Technology and Transport, Reference No.: KPLGY 2017.434.1.1)

Hozzászólások

Log in or register to comment!

Login Registration